Innovations in Agriculture

A continuously flowing farm Grain Dryer has grain dropping through columns that have perforated screens on both the inside and outside. They have either LP or Natural Gas burners inside and large fans blow the hot air through the columns as the corn falls to lower moisture content and then most blow unheated air across the grain to cool it down so that it can be stored.

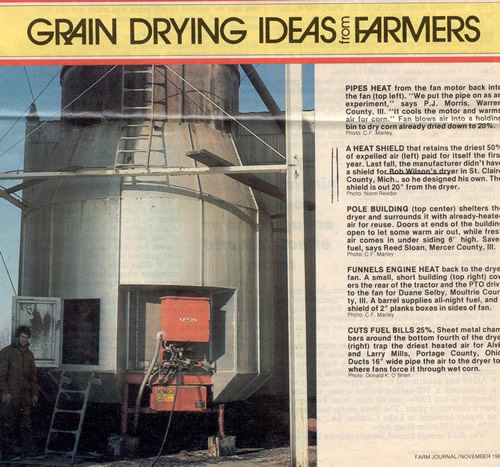

In the late 1970’s Manufactures of Rectangular Dryers began offering shields to capture a portion of the hot air and re-use it in order to reduce fuel consumption. No Manufacturer offered a Heat Recovery system for a Round Dryer. Robert Wilson designed and built a Heat Recovery System for a Round Dryer that was featured in Farm Journal Magazine.

A dozer blade on the front of a large 4WD tractor is a necessity for pushing dirt and fallen trees on farms a great distance from the home farm. When Wilson Grain LLC purchased a Challenger tractor, a dozer blade system fitted for that Model would have cost approximately $40,000.

Joe Stover designed and built the entire mounting and pivot system and brush guard in the farm shop for less than 7% of the new cost. In addition, on the right side there is a Rock Box with trap door.

When operating a multitude of farms that can be 30-35 miles apart with limited personnel, it is very important to have quick access to transportation if something breaks and for a ride home at night. Every Wilson Grain tillage implement has rear hitch assembly and pickups have a permanently mounted extendable front tow bar.